Vertical Slicer CV-4

Dimensions : 24 x 49 x 54 inches

Weight : 320 lbs

Certification: CE/ NSF

The vertical slicer is designed to cut boneless products. The temperature of the product to be cut depends on the type of product and thickness of the cut being able to oscillate between 0ºC and -10ºC.

Cutting precision

- Uniformity in weight, shape, and thickness

- Electrically regulated cutting thickness

High production

- 4 high-capacity loaders

- Up to 60 r.p.m.

Safety

- IP69K safety barriers

- Brake-assisted disc

Warranty

1 Year Standard Warranty

Financing Available

Orders Over $500

Vertical Slicer CV-4

The production necessities are different depending on each company, and this is the reason why at Mainali this has been always the starting point, offering particular solutions adapted to the necessities of each client

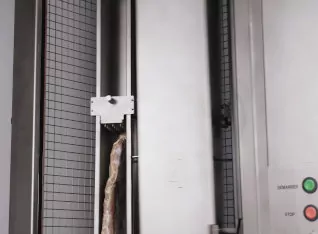

1. Cutting Edge Safety Sensors

Introducing our cutting-edge magnetic safety sensor technology. A reliable and versatile solution that ensures the utmost safety in a wide range of applications. You and your staff can experience the latest in safety technology.

2. Robust Product Hopper

Introducing our robust product hopper, designed to handle large volumes with ease. Its spacious capacity holds up to 50 pounds of product and ensures uninterrupted production, allowing for efficient and continuous workflow.

3. Time Saving Paper Applicator

Discover the game-changing optional paper applicator that streamlines your workflow, saving you valuable time and money. Its seamless integration with our equipment ensures precise and efficient paper application between patties thus reducing waste, maximizing productivity and perfectly separating your portions.

4. Convenient Power And Speed Control

Unleash the power of our equipment with the push of a button ensuring ultimate convenience and safety in your professional kitchen. Control the speed effortlessly tailoring the machine's performance to your unique needs. Precision and convenience every time.

5. Efficient Outfeed Belt

Experience unparalleled efficiency with our optional outfeed belt, designed to optimize your production process. Streamline your production by seamlessly integrating with our products ensuring smooth a continuous product flow, eliminating bottlenecks and increasing overall productivity.

6. Effortless Portion Control

Take control of portion precision with our innovative portion controls. Designed to accurately measure and dispense precise amounts, they empower you to minimize waste, maintain consistent serving sizes, and maximize cost efficiency for your business.

7. Quick Release Controls

Intuitively designed, convenient quick release controls engineered for effortless disassembly. With a simple and easy to use design, you can easily dismantle and clean our equipment, saving valuable time and ensuring optimal hygiene standards.

8. Customizable Product Forming Plates

Unlock endless possibilities with our customizable product forming plates. Tailor-made to meet your unique needs, these plates allow you to create a wide range of product shapes and sizes, offering versatility and flexibility to achieve your desired outcomes. Revolutionize your production process and unleash your creativity with our innovative customizable product forming plates.

1. Cutting Edge Safety Sensors

Introducing our cutting-edge magnetic safety sensor technology. A reliable and versatile solution that ensures the utmost safety in a wide range of applications. You and your staff can experience the latest in safety technology.

2. Robust Product Hopper

Introducing our robust product hopper, designed to handle large volumes with ease. Its spacious capacity holds up to 50 pounds of product and ensures uninterrupted production, allowing for efficient and continuous workflow.

3. Time Saving Paper Applicator

Discover the game-changing optional paper applicator that streamlines your workflow, saving you valuable time and money. Its seamless integration with our equipment ensures precise and efficient paper application between patties thus reducing waste, maximizing productivity and perfectly separating your portions.

4. Convenient Power And Speed Control

Unleash the power of our equipment with the push of a button ensuring ultimate convenience and safety in your professional kitchen. Control the speed effortlessly tailoring the machine's performance to your unique needs. Precision and convenience every time.

5. Efficient Outfeed Belt

Experience unparalleled efficiency with our optional outfeed belt, designed to optimize your production process. Streamline your production by seamlessly integrating with our products ensuring smooth a continuous product flow, eliminating bottlenecks and increasing overall productivity.

6. Effortless Portion Control

Take control of portion precision with our innovative portion controls. Designed to accurately measure and dispense precise amounts, they empower you to minimize waste, maintain consistent serving sizes, and maximize cost efficiency for your business.

7. Quick Release Controls

Intuitively designed, convenient quick release controls engineered for effortless disassembly. With a simple and easy to use design, you can easily dismantle and clean our equipment, saving valuable time and ensuring optimal hygiene standards.

8. Customizable Product Forming Plates

Unlock endless possibilities with our customizable product forming plates. Tailor-made to meet your unique needs, these plates allow you to create a wide range of product shapes and sizes, offering versatility and flexibility to achieve your desired outcomes. Revolutionize your production process and unleash your creativity with our innovative customizable product forming plates.

Designed for cutting boneless products. The temperature of the product to be cut depends on the type of product and thickness of the cut being able to oscillate between 0ºC and -10ºC.

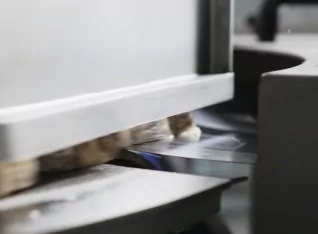

The cutting disc is positioned horizontally.

The product is placed vertically on rotating support with 4 loaders so that each revolution of the support makes multiple cuts. The loaders can be customized for each type of product.

The cutting disc and the rotating loader support are driven by geared motors connected to electronic variable speed drives.

The cutting thickness is electrically adjustable, and the disc position can be fixed.

Each loader of the rotating support has a pneumatic actuator that lifts the product pusher to facilitate product loading. During the cutting operation, the cylinder pushes towards the base to fix the product in the loader and achieve maximum homogeneity in weight, shape, and thickness.

The cut product is evacuated by a variable speed conveyor belt.

The equipment guards are made of stainless steel mesh with side access doors. The cutting disc has stainless-steel protection. The CV-4 vertical slicer has IP69K barriers with heated resistors.

Integrated electrical panel with variable speed drives for the cutting disc, the product rotating support, and the conveyor belt.

The Vertical Slicer CV-4 is built in stainless steel and food-grade plastic materials.

Request more information, a quotation or an online demonstration of our vertical slicer CV-4.

Technical data

Cutting precision

Controlled and constant pressure system to achieve uniformity in weight, shape and thickness.

High Production

High-capacity loading zone, for very high production rates

Circular cutting disc

Circular disc cutting system for higher product quality.